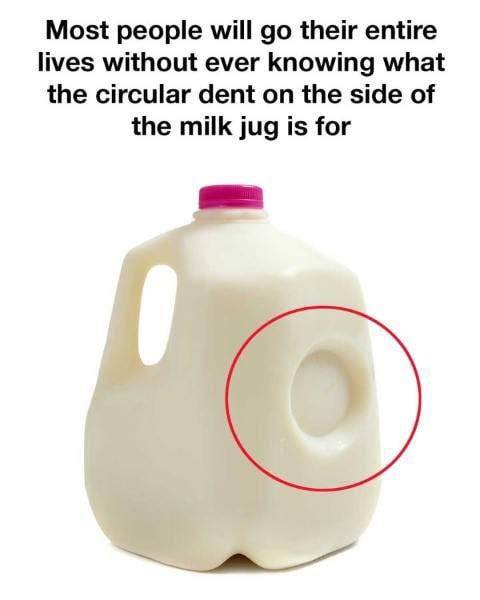

If you’ve ever taken a carton of milk out of the fridge and noticed a small round dent on the side of the jug, you’re not alone — but you’re also not alone if you never gave it a second thought.

At first glance, that dent might look like a manufacturing flaw or some kind of accidental indentation. But in truth, that tiny dip in the plastic isn’t a mistake at all. It’s a clever piece of engineering that plays a major role in how your milk jug works — and it’s one of those small details that quietly makes life easier and safer.

Let’s take a closer look at why that dent is there, and how such a small feature reflects big thinking about convenience, sustainability, and smart design.

It’s Not Just Decorative — It’s Functional Engineering

Believe it or not, the dent in your milk jug is purpose-built. It’s not the result of poor molding or careless manufacturing. It’s there to help the jug hold up under pressure — literally.Glass jug alternatives

Milk is heavy, and plastic jugs are thin by design. When a jug is filled, the weight and pressure of the liquid can cause the container to bulge, warp, or crack over time. Add temperature fluctuations (like milk going from cold storage to a warm car trunk), and the plastic has even more stress to endure.

That’s where the dent comes in. It acts like a flex zone — a built-in buffer that allows the jug to subtly expand or contract without breaking or buckling.

So the next time you set a jug on the counter and hear a quiet pop or see it shift slightly, that dent is doing its job — adjusting to pressure and preventing a mess.

Built to Absorb Shock — A Quiet Spill Saver

Milk recipe book

Ever dropped a jug of milk? We’ve all done it at some point. If you’ve been lucky enough that it didn’t burst open and drench your kitchen floor, thank the dent.

The indented area on the side of the jug helps it absorb some of the impact force when dropped. It works a bit like a cushion — giving just enough to soften the blow without letting the plastic split apart.

In a way, it’s like a built-in airbag for your milk.

A Smart Way to Use Less Plastic — And Help the Planet

There’s another reason manufacturers include that dent — it allows them to use less plastic while still maintaining a strong, stable jug.

Milk processing equipment

How does that work? Think of it like an arch in architecture: by curving and shaping the plastic in the right way, engineers can strengthen the jug without needing to thicken the walls. That saves money, materials, and energy — and ultimately makes the jug more eco-friendly.

In fact, many companies are actively working to reduce the environmental footprint of their packaging, and this tiny design element plays a part. Sustainable packaging isn’t just about cardboard straws and biodegradable bags — sometimes, it’s about the quiet innovations you don’t even notice.

Easier to Crush and Recycle — A Win for Waste Reduction

Once the milk is gone and the jug is rinsed, it’s headed for the recycling bin — and guess what? That dent helps there too.

Glass jug alternatives

Because it acts like a weak point in the structure, it allows the jug to be easily crushed, saving space in your recycling bin and making it easier to compact during the recycling process. Less volume means more efficient transport and processing at recycling centers, which reduces overall energy use and emissions.

So when you flatten a jug before tossing it into the bin, you’re helping the system run more smoothly — thanks to that little dent.

Branding with Purpose — Not Just a Pretty Face